DESCRIPTION

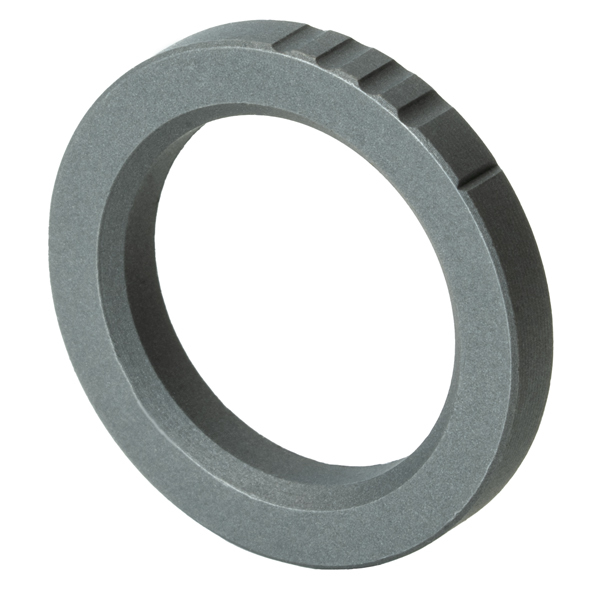

The AccuWasher® Gen 2 Muzzle Device Alignment System is the ultimate solution for precise and repeatable muzzle device alignment. Unlike traditional crush washers, this mono-shim system is precision lathe-turned on both faces, ensuring a certified guaranteed circular thickness uniformity of .0001” for unparalleled accuracy.

- Precision Machined Mono-Shim: Provides exact muzzle device timing with external markings for easy identification.

- Unmatched Strength & Durability: Made from high-strength steel, equal to or stronger than barrel steel, ensuring failsafe strength.

- No Shear-Slip or Yielding: With its monolithic construction and significant thickness, AccuWasher shims resist deformation under heavy impact or bending loads.

- Maintains Accuracy & Safety: Eliminates alignment issues caused by traditional shims, preventing accuracy loss even under rough handling.

- Reliable for Suppressors & Muzzle Brakes: Provides the highest insurance against misalignment due to bumps, drops, or impacts.

- Fast, Intuitive Installation: External markings make it the easiest and most precise alignment system on the market.

Note: The AccuWasher Alignment System can be used with any brand muzzle device.

SHIM ADAPTERS

New AccuWasher® Shim Adapters can be used to expand compability and fitment to nearly all common barrel threads, including metric.

EASY IDENTIFICATION

Shims are individually marked for easy identification.

CHAMFERED EDGE

Each shim is chamfered on one side to allow clearance for barrels with radiused thread shoulders.

FREQUENTLY ASKED QUESTIONS

The AccuWasher® Gen 2 is an upgraded version of the Precision Armament original single-shim muzzle device alignment system. It allows for precise, repeatable alignment of muzzle brakes, compensators, and suppressor mounts—eliminating the guesswork and inconsistency of peel washers and crush washers. Gen 2 features new shim sizes, thinner profiles, and adapter compatibility for broader use across different thread sizes and barrel profiles.

Crush washers are perfectly acceptable to use on any open aperture muzzle device, such as the standard A2 birdcage flash hider. However, our opinion is they should never be used on any baffle style muzzle device where the clearance hole is only slightly larger than the bullet. Firstly, crush washers come to a knife edge on both mating surfaces - it is likely for this reason that a muzzle device is already misaligned just sitting on the crush washer before it is even torqued down. More importantly, it relies on the principle that the washer will deform uniformly while it is being crushed. This requires that the material is uniform and that you apply a perfectly pure torque load normal to the bore. This is very unlikely (for anyone who has installed one) when you're putting all your might into the 30-60 ft-lbs of torque they often require. The consequence of this misalignment is a baffle strike causing bodily harm at worse and impaired accuracy at best.

On average, each pack will get you about 9 installations before a single replenishment shim is needed. Instead of increasing the price on all muzzle devices to include the Accu-Washer Alignment System, it makes more sense for a user to buy one pack separately and use it across multiple installations.

The Gen 2 system offers several improvements over the original:

| Feature | Gen 1 | Gen 2 |

|---|---|---|

| Shim Sizes | 1/2” and 5/8” kits only | Now includes 1/2”, 5/8”, and 3/4” kits |

| Outside Diameter (OD) | 1/2” shim: 0.750” | 1/2” shim: 0.725” (smaller for a sleeker fit) |

| Shim Thickness | 5/8” shim: 0.060”-0.100” | 5/8” shim: 0.040”-0.080” (thinner for finer adjustment) |

| Compatibility | Limited to fixed thread sizes | Now compatible with all common thread sizes and barrel profiles via shim adapters |

| Interchangeability | 1/2” shims are compatible | 5/8” Gen 1 and Gen 2 shims are not interchangeable |

| Aesthetic | Standard fit | More flush and professional finish with adapters |

The shim adapter serves three key functions:

- Expands compatibility - Allows use of the AccuWasher system on multiple thread sizes and barrel profiles that were previously unsupported.

- Improves fit and finish - Enables shooters to size up to achieve a cleaner visual transition between the muzzle device and barrel shoulder.

- Adds modularity - Makes the Gen 2 system future-proof and more versatile for both OEMs and end-users.

Note: If included in your kit, the adapter should be installed before the indexing shim.

Yes. The new shim adapters are backwards compatible with the original system. This means current Accu-Washer users can upgrade their setup without replacing their entire kit.

Each shim is laser-marked with a series of thick and thin dashes:

- Thick dashes = 5

- Thin Dashes = 1

For example, a shim with 4 thick dashes and 1 thin dash equals shim #21.

Use the included timing chart to determine which shim number aligns your muzzle device properly.

Yes. Shim adapters are available in both 1-pack and 3-pack options and can be purchased separately through our website or authorized dealers.

Absolutely. Despite all the added features and compatibility improvements, Gen 2 maintains the single-shim design, which offers better alignment, accuracy, and repeatability compared to systems requiring multiple stacked shims.

The reason the original 5/8” Accu-Washer® replacement shim is still available while the original 1/2” shim has been discontinued comes down to design compatibility between Gen 1 and Gen 2 systems.

Here's the breakdown:

- Original vs. Gen 2 - 1/2” Shim:

The outside diameter (OD) of the Gen 2 1/2” shim is 0.025” smaller than that of the original version. This dimensional difference makes the original 1/2” shim compatible with Gen 2, and since Gen 2 is now the active production version, the original 1/2” shim was phased out. - Original vs. Gen 2 - 5/8” Shim:

The OD of the Gen 2 5/8” shim is identical to the original, even though the thickness range has been slightly reduced (for finer timing control). This means that original and Gen 2 5/8” shims are not interchangeable, allowing the original 5/8” shim to remain available for purchase.

In short:

- ❌ 5/8” original shim ≠ is not compatible with Gen 2 → still offered.

- ✅ 1/2” original shim = compatible with Gen 2 → discontinued.

Choose the OD size that most closely matches—or exceeds—the diameter of your barrel at the muzzle. Here's a general guide:

- If your barrel measures under 0.725", the 0.725" OD shim will provide the cleanest fit.

- If your barrel is between 0.725" and 0.825", the 0.825" OD shim is the best match.

- For muzzle diameters over 0.825", go with the 0.925" OD shim—our largest size.

Larger OD shims can still be used with smaller barrels, especially when paired with large-diameter muzzle devices where visual matching matters less. Choose based on the best balance of fit and final appearance.

First, make sure the threads on your barrel and muzzle device are completely clean and free of all debris. Any contamination can limit the rotation. Next, applying a moly-grease or CLP-type lubricant to the threads on the brake and barrel will provide further rotation for the same torque. We suggest you apply generously, then run the brake on and off the barrel a couple times to work it in, then wipe up any excess. The coefficient of friction between the threads is what limits your rotation, cutting this coefficient in half with grease can give you twice as much rotation. You may also apply some lubricant to each side of the shim as there is friction in the works here too. Lastly, a little elbow grease. Since the Accu-Washer shims are used to adjust your brake in discrete intervals, it is inherent that the torque required for proper alignment will fall in a range. The torque load specified in the instructions is merely the minimum required so your device does not rattle free, however you will need to continue to apply torque beyond this to achieve alignment. Higher torque installs may require holding the rifle in a barrel vise.

We've created an easy-to-follow and detailed instruction manual with a printable timing chart. If you have questions, feel free to contact our service team:

Phone: 585-593-4975

Email: sales@precisionarmament.com

SPECIFICATIONS TABLE

| AW500G2 | AW625G2 | AW750G2 | ||

| ID | .500" (1/2") | .625" (5/8") | .750" (3/4") | |

| OD | .725" | .825" | .925" | |

| Barrel Thread Size | Thickness Range | .060" - .094" | .040" - .080" | .040" - .080" |

| 1/2x24 | Kit SKU (Shim QTY) | A00505 (21) | ||

| Shim Kit Price | $29.99 | |||

| Shim Adapter SKU (QTY) | ||||

| 1/2x28 (1/2x32 - 1/2x36) |

Kit SKU (Shim QTY) | A00500 (18) | A00502 (18) | A00503 (18) |

| Shim Kit Price | $24.99 | $28.99 | $29.99 | |

| Adapter Included With Shim Kit (QTY) | A00240 (3) | A00343 (3) | ||

| 9/16x24 | Kit SKU (Shim QTY) | A00510 (21) | ||

| Shim Kit Price | $32.99 | |||

| Adapter Included With Shim Kit (QTY) | A00250 (3) | |||

| M15x1 | Kit SKU (Shim QTY) | A00554 (20) | ||

| Shim Kit Price | $32.99 | |||

| Adapter Included With Shim Kit (QTY) | A00288 (3) | |||

| 5/8x24 | Kit SKU (Shim QTY) | A00520 (21) | A00521 (21) | |

| Shim Kit Price | $27.99 | $32.99 | ||

| Adapter Included With Shim Kit (QTY) | A00364 (3) | |||

| 11/16x24 | Kit SKU (Shim QTY) | A00530 (21) | ||

| Shim Kit Price | $32.99 | |||

| Adapter Included With Shim Kit (QTY) | A00372 (3) | |||

| 3/4x24 | Kit SKU (Shim QTY) | A00540 (21) | ||

| Shim Kit Price | $29.99 | |||

| Adapter Included With Shim Kit (QTY) | N/A | |||

| M18x1 | Kit SKU (Shim QTY) | A00557 (20) | ||

| Shim Kit Price | $32.99 | |||

| Adapter Included With Shim Kit (QTY) | A00394 (3) |

Reviews

-

Service and Product

Precision armament is single handedly the best company I have dealt with in a costumer service respect. I made the mistake of ordering the .725 when I need .925, and so I emailed over the weekend. Not only did they respond not even 20 minutes after their opening buisness hours, but they switched my order out before it shipped. The package never arrived due to my billing address and shipping address not being the same, and so I emailed again. Not only did they reply promptly again, but they shipped it with 2 day shipping through fedex, so that my order arrived by the beginning of the next week. My precision armament M472 Muzzle brake (which is a game changer) is now timed correctly with their Gen 2 Accuwasher set, and I will surely be back again when in need of barrel accessories.

-

Accu Washer gen 2

Highly recommended manufacturer this the Best Shim system out there!!!

-

Best Shim Setup out there!

is the Best Shim system out there!!! It gives you great adjustment options and allows you to shim multiple rifles with a single kit. Anyone who has timed a brake is familiar with shims that tear or become deformed under pressure, regardless of whether they are original equipment or aftermarket components. Not with these! You will see an enormous difference with this setup. Easy to identify thickness based on hash/line setup. Any time we need to time a muzzle brake this will be the systems used on our setups!! Thanks for great systems!

-

Best system for a muzzle device

Much better than using shims or Crush washers. Once you figure out the system it's easy to get it timed correctly. My only complaint is the markings on the side that indicate the size. Sometimes it's hard to tell the difference in the size of the hash marks. I wish there was a way they could color code them or make them a little bit more prominent. Hopefully they read this and maybe they've heard the same for other customers.

-

AccuWasher gen 2

Item functions as intended. I’ve used Precision Armament shims and muzzle devices in the past and will continue to use them in the future. Highly recommended manufacturer

-

Accuwasher

Great product. Works as advertised. I.was able to properly time all my firearms with muzzle devices.

-

Best Option for Mounting

Did my first ever muzzle brake time and install with this set. Using one Accuwasher to time, rather than a stack of flimsy shims, is the best possible way to approach the task. I tried the "muzzle device manufacturer" shims first, and those were more hassle than they were worth. For a first-timer, it took me maybe 5 minutes to figure out the Accuwasher method. 10/10.