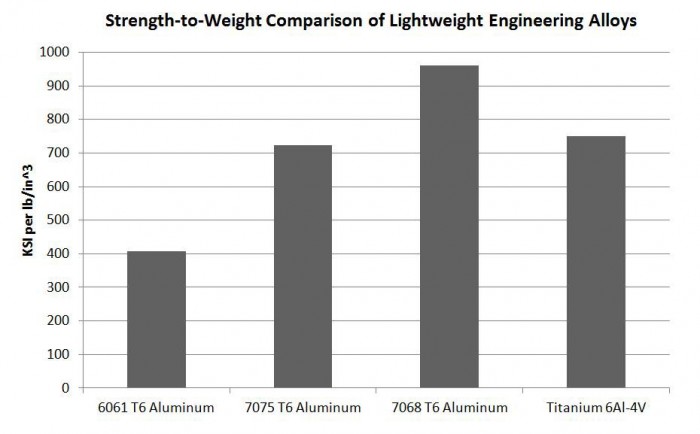

So what are you truly purchasing in terms of performance? Below is a comparison of how Tennalum® 7068 stands up next to the lightweight alloys used by the rest of the firearms industry.

Aluminum Alloys

First a little background - Aluminum (Al) is the single most abundant atomic metal element found in the earth's crust. It's a remarkable metal due to its low material density and superb ability to resist corrosion. Pure aluminum, however, is soft, weak, and ductile making it a poor candidate for any high strength application. Though, when mixed with other elements, an alloyed metal can be created with more favorable mechanical properties. The alloyed metal still retains its low density and corrosion resistance but with substantial increases in both strength and hardness. Today, these alloys are used in almost every modern applications where aluminum is found. There are literally hundreds of different alloys that have been engineered and optimized for specific applications.

6061 alloy is the single most commonly used aluminum alloy today. It is readily available and inexpensive, making it extremely popular for general purpose use. In fact, when you see a product described as being made from 'alloy aluminum' or 'billet aluminum', or perhaps 'aircraft aluminum', but the name of the alloy is not specified, it is a safe bet that it is made from 6061. Virtually all lightweight firearm parts on the market today (optics rails & rings, bottom metal, bolt knobs, etc.) are machined from extruded 6061 alloy. The title 'aircraft' aluminum, however, is somewhat misleading since 6061 is not a high strength alloy by any means. With a mere 40 KSI yield strength, it's use on aircraft is limited to non-critical, low stress components.

7075 alloy is the most common high strength true 'aircraft' aluminum alloy used today. Its typical yield strength (73 KSI in the T6 condition) is comparable to certain steels giving the alloy a remarkably high strength-to-weight ratio. In fact, it's worth noting that its specific strength is comparable to that of 6Al-4V Grade 5 Titanium. However, 7075 is roughly 2-3 times more expensive than 6061. For this reason, it is not as commonly used in the firearms industry as 6061, except in tactical applications where increased strength is a necessity.

Tennalum 7068 Ultra-Strength Aluminum - The Ultimate Alloy

Circa 2000, the Ordnance industry requested development of an ultra-high strength, lightweight alloy with corrosion resistance equal or better than 7075. In response, Tennalum Inc. (a division of Kaiser Aluminum Corp.) developed an ultra-strength alloy called 7068-T6511 - commonly known as Tennalum® 7068. With a yield strength of 99 KSI (683MPa) it has the highest mechanical strength of all commercially available aluminum alloys (2.5 times stronger than 6061, and 35% stronger than 7075) and exceeds that of many steels. In fact, it's yield strength is approaching that of pre-hardened (HRC 26-32) 41XX and 400 series stainless steels but at a third of the weight. In strength-to-weight ratio, Tennalum® 7068 out performs nearly all other engineering alloys in existence (33% better strength-to-weight performance than 7075, and 28% better performance than 6Al-4V Grade 5 Titanium). However, due to its higher cost (3-4 times that of 6061) and limited availability, it has seen very little commercial use. But for many applications there is no better alloy, not even Titanium.

Tennalum® is a registered trademark of Kaiser Aluminum Corp.