26th Nov 2025

Hypertap® Ti Muzzle Brake - Ultralight Recoil Control Device

The Titanium Advantage for Ultralight Recoil Control

Meet the Titanium Hypertap® Ti muzzle brake — a featherweight, aerospace-grade titanium muzzle brake engineered to give ultralight and precision hunters full-size recoil control without the weight penalty. Designed around our proven Hypertap baffle geometry and precision CNC craftsmanship, the Hypertap Ti muzzle brake tames harsh recoil and muzzle climb while preserving balance and portability on the lightest rifles. Read on to learn why titanium is the material of choice (and where it isn’t), what makes the Hypertap Ti brake superior, how to choose between Slim and Standard, and which ultralight platforms pair best with this high-performance muzzle brake.

Why Titanium for a Muzzle Brake?

When designing a high-performance muzzle brake for ultralight rifles, material choice is critical. Titanium offers several compelling advantages — but also carries a few trade-offs. Here’s a breakdown of what you need to know before selecting a titanium brake.

Advantages of Titanium

• Ultra-light construction: Titanium weighs roughly half as much as steel. The Hypertap Ti Slim weighs 1.7 oz, while the Standard body version weighs about 2.7 oz — delivering maximum recoil reduction with minimal added mass.

• High strength-to-weight ratio: Aerospace-grade titanium provides exceptional structural performance and durability relative to its weight.

• Corrosion resistance: Titanium is naturally resistant to oxidation and chemical corrosion — it won’t rust, even in harsh field or marine environments.

• Minimal impact on rifle balance: Because it adds almost no weight at the muzzle, the brake preserves the rifle’s natural balance and handling — crucial for hunters and back-country shooters.

• Reduced point-of-impact (POI) shift: Adding mass to the muzzle can alter barrel harmonics and shift POI. The ultralight Hypertap Ti brake minimizes this effect, helping rifles maintain their zero after installation.

Trade-Offs & Considerations

• Erosion and sparking: Titanium has lower erosion resistance than hardened steel under sustained high-pressure gas flow. Over long use, it can wear faster and may occasionally produce sparks. For that reason, the Hypertap Ti muzzle brake is best suited for bolt-action or low-volume precision applications rather than continuous rapid-fire use.

• Higher cost and machining complexity: Titanium’s properties make it more challenging to machine precisely. Each Hypertap Ti unit is CNC-cut and finished to tight tolerances — the premium price reflects both the material and the craftsmanship required.

Why the Hypertap Ti Muzzle Brake Delivers Superior Performance

Not all titanium brakes are created equal. The Hypertap Ti muzzle brake builds on our proven Hypertap® geometry — a design known throughout the industry for its outstanding recoil-reduction efficiency — and refines it specifically for ultralight rifle applications. Every feature is purpose-engineered to provide maximum control with minimum added weight.

Engineered for Efficiency

• Proven Hypertap baffle geometry: The same high-efficiency internal gas paths used in our flagship Hypertap® series are carried over to the titanium model. This design redirects propellant gases with exceptional precision to reduce recoil and muzzle rise more effectively than conventional baffle styles.

• Compact 3-baffle layout: Ultralight rifles demand compact components. The Hypertap® Ti brake uses a shortened three-baffle design that preserves up to 80% recoil reduction, depending on cartridge and bullet weight, while maintaining a smaller footprint ideal for hunting and pack rifles.

• Top ports pre-drilled for maximum compensation: The top porting is engineered to aggressively counteract the extreme muzzle climb often associated with ultralight builds. Each port is pre-drilled to its maximum effective diameter for consistent, balanced gas venting.

• Integrated timing nut for easy installation: The Hypertap Ti brake includes an integrated self-timing nut that eliminates the need for shims or crush washers. This system enables quick and easy installation and alignment.

• Aerospace-grade titanium construction: Each brake is precision CNC-machined from high-strength Grade 5 titanium (6Al-4V) and finished to exacting tolerances making it ideal for ultralight rifles.

• Uncompromising recoil control with minimal mass: At only 1.7 oz (Slim) or 2.7 oz (Standard), the Hypertap Ti brake delivers elite recoil mitigation without compromising rifle balance or portability.

Real-World Results

Field testing and customer feedback confirm what the data shows: rifles equipped with the Hypertap Ti muzzle brake exhibit noticeably reduced felt recoil, faster sight recovery, and improved shooter comfort — even in lightweight, high-recoil calibers. For serious hunters, precision shooters, and anyone running an ultralight build, it provides the control of a full-size brake at a fraction of the weight.

Slim vs. Standard — How to Choose

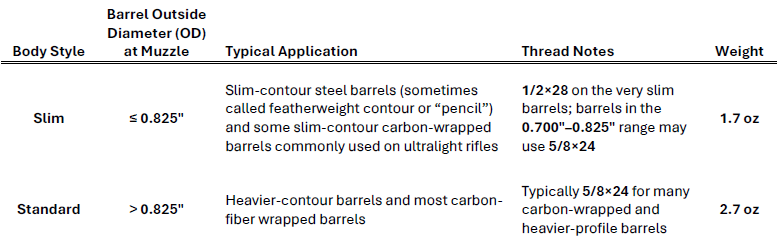

The Hypertap Ti muzzle brake is offered in two body profiles to ensure an optimal fit across a wide range of barrel diameters. Both body styles deliver similar recoil performance; the difference lies in physical dimensions and barrel compatibility.

Choosing the Correct Body Style

Practical Thread Guidance

• 1/2×28: Slim-contour steel barrels (sometimes called featherweight contour or “pencil”) often lack the muzzle diameter needed for 5/8×24 threads and therefore commonly use 1/2×28 — however, barrels measuring in the 0.700″–0.825″ outside-diameter range may use 5/8×24.

• 5/8×24: Heavier-profile barrels and most carbon-wrapped barrels commonly use 5/8×24, but always confirm your barrel’s thread spec before ordering.

• Thread spec alone isn’t a reliable indicator of body fit — always measure muzzle OD.

How to Measure

- Measure muzzle OD at the shoulder — use a set of calipers to measure the outside diameter of your barrel where the muzzle device will seat. (Tip: an affordable digital caliper — the kind sold online for about $10 — is accurate enough for this job and a useful tool to have around for many other measurements).

- Compare to the fit table — if the measurement is 0.825″ or smaller, select Slim; if larger, select Standard.

- Confirm thread pitch — verify whether your barrel is 1/2×28 or 5/8×24 before ordering.

Why Two Sizes?

Ultralight rifle designs vary widely in barrel construction. Slim-contour steel barrels typically use smaller outside diameters to save weight, while carbon-fiber–wrapped barrels can have larger external contours to provide stiffness without adding mass. Offering two body sizes ensures the Hypertap® Ti muzzle brake matches both classes of barrels for balanced aesthetics and correct fit — keeping the muzzle device aligned with the barrel contour and protecting the barrel’s thread shoulder from exposure or interference.

Model Compatibility & Sizing — Which Body to Choose for your Rifle

Below are rifle models we’ve identified as ideal fits for the Hypertap Ti muzzle brake. These recommendations are based on typical factory barrel contours and diameters — always verify your muzzle OD and thread pitch before ordering.

Slim Body — Recommended Models

Best for light-contour steel barrels and some slim-contour carbon-fiber barrels (≤ 0.825″ OD).

Steel Barrels (≤ 0.825″ OD):

• Bergara Crest (steel, fluted barrel)

• Browning X-Bolt 2 Mountain Pro SPR

• Christensen Arms Mesa FFT

• Christensen Arms Evoke

• Howa Superlite

• Howa Stalker

• Seekins Precision Element (steel, fluted barrel)

• Seekins Precision PH2 & PH3

• Tikka T3x Superlite

• Weatherby Mark V Backcountry 2.0 & 2.0 Ti

• Weatherby Mark V High Country

• Weatherby Mark V Camila

Carbon-Fiber Barrels (≤ 0.825″ OD):

• Seekins Precision Element M3

• Seekins Precision Hunter

Standard Body — Recommended Models

Best for heavier-contour barrels and most carbon-fiber–wrapped barrels (> 0.825″ OD).

Steel Barrels (> 0.825″ OD):

• Sig Cross

Carbon-Fiber Barrels (> 0.825″ OD):

• Bergara Crest Carbon

• Bergara MgMicro Lite

• Bergara Wilderness Ridge Carbon

• Christensen Arms Ridgeline

• Christensen Arms Summit Ti

• Christensen Arms MPR

• Christensen Arms TFM

• Christensen Arms Traverse

• Christensen Arms Modern Carbon Rifle

• Howa Elevate

• Savage Arms 110 Ultralite

• Savage Arms Klym

• Savage Arms Ultralite Elite

• Springfield Armory Waypoint 2020

• Weatherby Mark V Backcountry Carbon

• Weatherby Mark V Carbonmark

Quick Fit Reminders

• Measure first: Use calipers to measure muzzle OD where the brake seats. If ≤ 0.825″, choose Slim; if > 0.825″, choose Standard.

• Thread check: Slim-contour steel barrels typically use 1/2×28; heavier and most carbon-fiber barrels use 5/8×24 — but always verify your exact thread spec.

• Unsure? Reach out — our team is here to help confirm your fit before you order.

- Phone: 585-593-4975

- Email: sales@precisionarmament.com