Introduction

Thread identification for rifle barrels is essential for proper maintenance, customization, and the installation of muzzle devices. This how-to guide outlines the safety precautions, methods and tools needed for accurate thread measurement. A detailed explanation of both American and metric thread standards is included. This tutorial aims to provide clear, step-by-step instructions to ensure precision and safety when working with rifle barrels.

Firearm Safety

Ensuring Safety Before Measurement

Before beginning any thread identification process, it is imperative to ensure the firearm is unloaded. Safety is paramount. The following steps should be strictly adhered to:

- Unload the Firearm: Remove all ammunition from the firearm. Remove or empty the magazine and ensure no ammunition is present.

- Visually Inspect the Chamber: Open the action and visually inspect the chamber to confirm it is empty.

- Remove the Bolt: If possible, remove the bolt from the firearm. This adds an extra layer of safety and makes the measurement process more straightforward.

These steps are non-negotiable to prevent accidents and ensure a safe working environment.

Tools for Thread Identification

Essential Tools

Thread identification requires specific tools, which range from basic household items to precise machine shop instruments. The primary tools include:

- Thread Pitch Gauge: Available in both imperial and metric units, these gauges are used to measure the number of threads per inch or per millimeter. They are readily available at hardware stores or online for around $20.

- Micrometer: This tool measures the outside diameter (OD) of the threads with high precision.

- Caliper: Useful for measuring both the OD and the pitch of the threads.

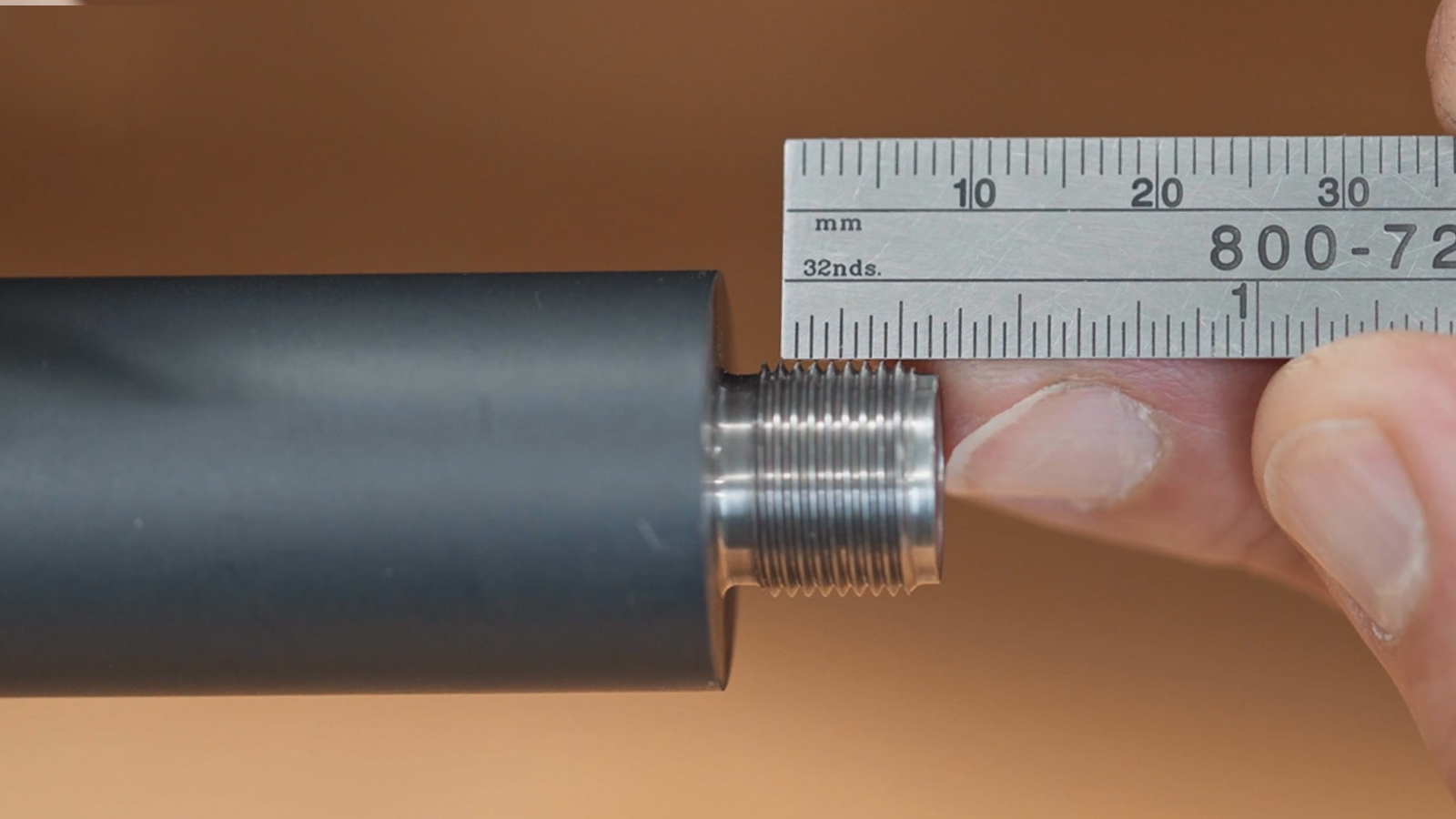

- Ruler: A simple ruler can be used for rough measurements but should be used with a straight edge for better accuracy.

Each tool serves a specific purpose and using them correctly is key to obtaining accurate measurements.

Understanding Thread Measurements

Outside Diameter (OD) and Thread Pitch

Threads are characterized by two main measurements: the outside diameter (OD) and the thread pitch. There are two types of threads commonly used in the firearms industry:

- UNS Threads (Unified National Standard): These threads use imperial units. The first measurement is the OD in inches, and the second is the number of threads per inch (TPI).

- Metric Threads: Here, the first measurement is the OD in millimeters, and the second is the distance between each thread in millimeters.

For UNS threads, a thread identified as 1/2x28 would have an OD of 0.500 inches and 28 threads per inch. For metric threads, an M15x1 would have an OD of 15 millimeters and 1 millimeter between each thread.

Measuring Outside Diameter

Accurately measuring the OD is crucial for identifying threads. The maximum OD is what the thread is identified as, though threads are typically cut slightly undersized for strength and fit purposes. Here's how to measure OD:

- Using Calipers: Place the calipers around the thread and read the measurement.

- Using a Ruler: If calipers are not available, use a ruler. Place a straight edge across the threads and measure from one side to the other using the ruler. Ensure your sight down the ruler to get an accurate measurement.

For example, a thread identified as 5/8” (0.625 inches) may actually measure between 0.615 and 0.625 inches due to the slight undersize.

Measuring Thread Pitch

Thread pitch can be measured using different methods depending on whether the thread is imperial or metric:

- Imperial Threads: Measure the number of threads over a certain distance. Place the ruler at the peak of one thread and count the number of threads over a quarter or half of an inch. Then determine the TPI by dividing the number of peaks by that distance. For instance, for a 24 TPI thread, you would count exactly 12 threads in a half-inch.

- Metric Threads: Measure the distance between each thread in millimeters. For best accuracy, use a metric ruler to measure across several thread peaks then divide the distance by the number of peaks. For example, if you count exactly 10 peaks across 10mm, it is a 1mm pitch thread. Alternatively, if you count exactly 10 peaks across 15mm, it is a 1.5mm pitch thread.

This ensures precise identification of the thread pitch, essential for compatibility and functionality.

Common Thread Sizes

American and Metric Standards

The most common thread sizes used in rifle barrels in the American and metric systems include:

- American (UNS) Threads: Sizes like 1/2x28, and 5/8x24 are prevalent. The first number is the OD in inches, and the second is the TPI. Less common thread sizes include 1/2x24, 9/16x24, 11/16x24 and 3/4x24.

- Metric Threads: Sizes such as M15x1, M18x1and M18x1.5 are common. The first number is the OD in millimeters, and the second is the pitch in millimeters.

For example, a 1/2x28 thread has an OD of 0.5 inches and 28 TPI, while an M15x1 thread has an OD of 15 millimeters and 1 millimeter pitch.

Conclusion

Identifying rifle barrel threads accurately is crucial for ensuring the safe and effective use of firearms. By following the outlined safety procedures, utilizing the correct tools, and understanding the measurements, anyone can identify threads accurately. Both UNS and metric threads are widely used, and understanding their differences is key to proper identification. Whether for maintenance, customization, or installation of a muzzle brake, precise thread identification ensures compatibility and functionality.